We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

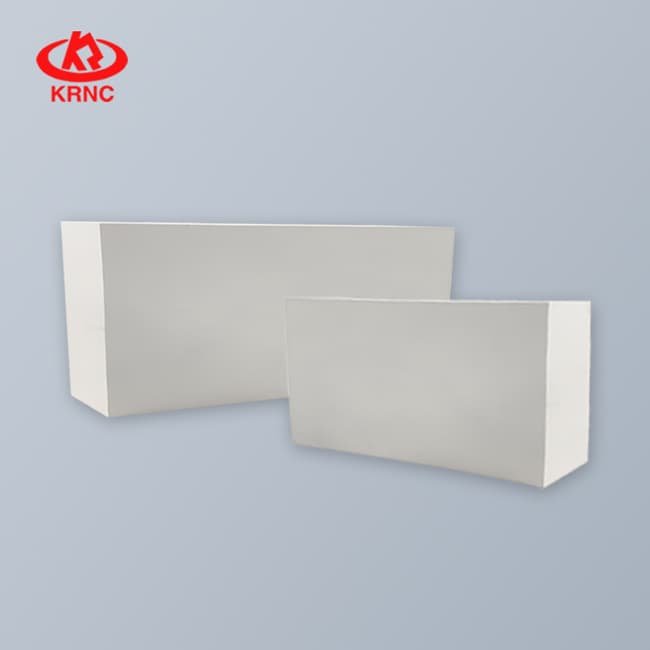

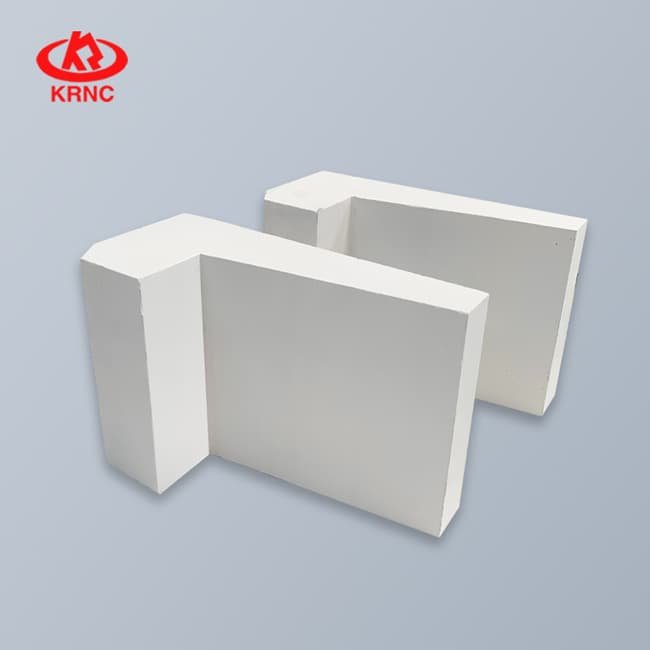

Fused cast AZS33 description

The dense microstructure of fused cast AZS-33 makes the brick have good corrosion resistance to liquid glass, and it is not easy to produce stones or other defects in the glass kiln.

Fused cast AZS33 application

Fused cast AZS33 is the most widely used and widely used product in the molten AZS series. It has excellent performance in preventing pollution of glass liquid. Fused cast AZS33 is the most widely used product in glass furnaces. It is widely used in the tank wall, tank bottom, superstructure and feed channel of glass furnaces.

Fused cast AZS33 chemical index

| Chemical Composition ( % ) | AZS 33 |

| ZrO2 | ≥ 32.5 |

| SiO2 | ≤ 15.5 |

| Al2O3 | Remains |

| Na2O | ≤ 1.4 |

| Fe2O3 + TiO2 | ≤ 0.25 |

Fused cast AZS33 physical index

| Physical characters | |

| Volume density (hardest part) | ≥ 3.80 |

| Cold crushing strength (Mpa) | ≥ 300 |

| Exudation Temp. of glass phase (℃) | ≥ 1400 |

| Refractorinessunder load of beginning (0.2MPa) | 1700 |

| Corrosion Resistance to glass melt 1300℃ x 10h ( mm/24hr ) | 1.5 |

Our service

Kerui has a complete pre-sale technical team and standardized customer service consultation process to provide customers with the design, production, construction and maintenance of the overall furnace refractory, and help customers quickly select the appropriate furnace construction and maintenance plan.

Wechat Us

Wechat Us