We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

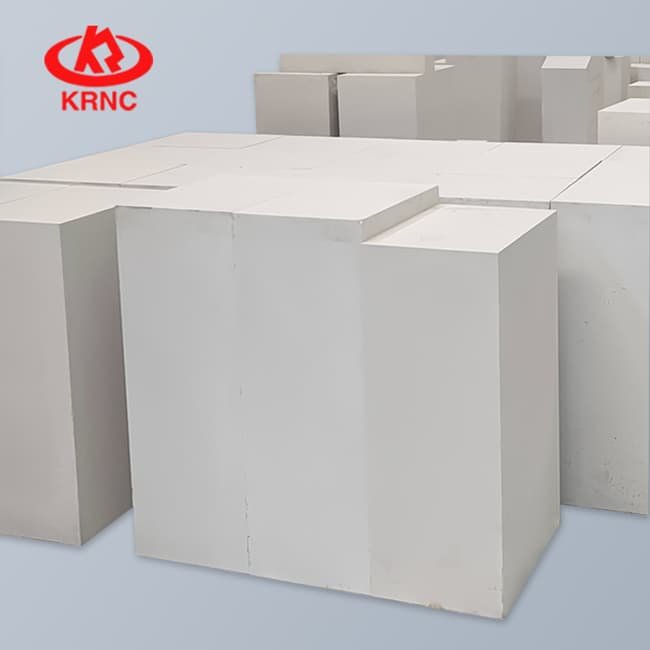

Description of refractory fused AZS brick

Electrofused zirconium corundum brick is also known as AZS brick. Refractory fused AZS brick is a white solid formed by melting and internalizing pure aluminum oxide powder and zirconium sand containing about 65% zirconia and 34% silica in electric melting furnace and then injected into the model for cooling.

The names 33, 36 and 41 in refractory fused AZS bricks are based on the Al2O3 content. For example, AZS33 refers to fused zirconium corundum bricks with 33% alumina content.

Features of refractory fused AZS brick

- High temperature resistance

- Erosion resistance

- Abrasion resistant

Production process of refractory fused AZS brick

Fused AZS brick manufacturing process is the selection of zircon sand and industrial alumina powder in 1:1 match, plus a small amount of NaZO(in the form of sodium carbonate added), B20 flux :(in the form of boric acid or borax added), mixed evenly, after 1800~1900℃ melting after casting molding, can be made containing zr02)33% of the fused AZS brick.

On this basis, fused AZS-36 brick and ASZ-41 can be prepared by using partially desilicated zircon sand as raw material.

Index of refractory fused AZS brick

| ltem | AZS-33 | AZS-33 | AZS-36 | AZS-36 | AZS-41 | AZS-41 |

| Y | H | Y | H | Y | H | |

| Al2O3≥ | 50 | 50.5 | 48 | 49 | 45 | 45.5 |

| ZrO2≥ | 32.0 | 32.0 | 35.0 | 35.0 | 40.0 | 40.0 |

| SiO2≤ | 15.0 | 16.0 | 13.5 | 13.5 | 13.0 | 12.0 |

| Na2O≤ | 1.5 | 1.5 | 1.4 | 1.4 | 1.3 | 1.3 |

| BD, PT.QX ≥ | 3.40 | 3.30 | 3.45 | 3.40 | 3.55 | 3.50 |

| BD, MS≤ | 3.50 | 3.45 | 3.60 | 3.55 | 3.70 | 3.65 |

| BD, WS≤ | 3.60 | 3.55 | 3.70 | 3.65 | 3.80 | 3.75 |

Detailed introduction of refractory fused AZS brick

Refractory fused AZS-33 brick has good corrosion resistance to glass liquid, is not easy to produce stones or other defects, and the possibility of producing small bubbles is very low. Therefore, AZS-33 fused zirconium corundum brick is a very widely used product in glass kiln, mainly suitable for the upper structure of the melting pool, the pool wall brick and paving brick of the working pool, the feed path, etc.

In addition to having the same eutectic crystal as AZS-33 electrofused zirconium corundum brick, refractory fused AZS-36 brick has more interlocking zirconium oxide crystals, while the glass phase content is reduced, so the corrosion resistance of AZS-36 brick is further enhanced, and the pollution to glass liquid is further reduced. Therefore, it is suitable for areas with fast flow rate and high temperature of glass liquid, such as melting pool wall brick, paving brick, charging port brick, etc.

Refractory fused AZS-41 fused brick contains more uniform distribution of zirconia crystals in addition to the eutectic crystals of silicon oxide and alumina. In the zirconium corundum brick system, its corrosion resistance is the best. Therefore, the key parts of the glass kiln are selected so that the life of these parts is balanced with other parts.

Refractory fused AZS brick manufacturer

Kerui refractory manufacturers are ready to provide you with free professional refractory consulting services. Kerui Refractory is a reliable refractory manufacturer for customers, and also hopes to become your best partner in China.

Wechat Us

Wechat Us