We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

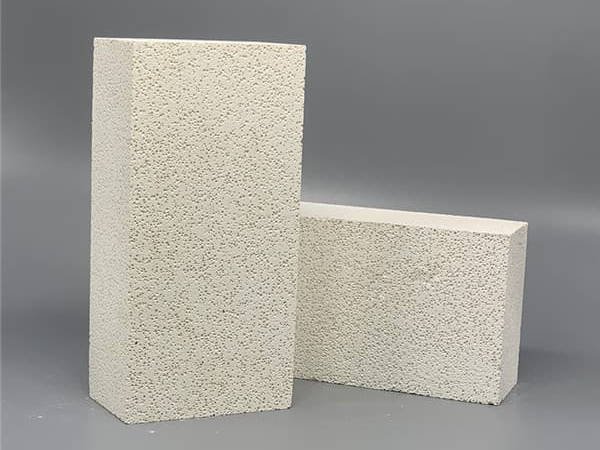

Product introduction of JM28 insulation brick

Mullite JM28 insulation brick can withstand high temperature of more than 1790℃. Load softening starting temperature 1600-1700℃, room temperature compressive strength 70-260MPa, good thermal shock resistance, high strength, low high temperature creep rate, low expansion coefficient, small heat coefficient, acid slag erosion resistance.

Advantages of JM28 insulation brick

Mullite JM28 insulation brick has the advantages of high purity, low impurity content, high temperature resistance, direct contact with flame, corrosion resistance to various atmospheres, low thermal conductivity, low hot melt, high strength, and has excellent thermal shock resistance, high dimensional precision, can be arbitrarily cut. Acting on high temperature kiln direct contact flame, good thermal insulation effect, high compressive strength, low thermal conductivity.

Application of JM28 insulation brick

Mullite JM28 insulation brick is widely used in residue gasifier, second stage ammonia reformer, carbon black reactor and refractory kiln. Product dimensions, physical and chemical indicators, service life are up to customer requirements.

Parameters of JM28 insulation brick

| JM-28 Model | Volume Density | Reheating Linear Change Rate | Cold Crushing Strength | Modulus of rupture | Thermal Conductivity | Al2O3 | SiO2 | Fe2O3 |

| - | g/cm3 | 1500℃*12h% | MPa | MPa | W/m·K | % | % | % |

| A | 0.8 | -1 | 2.5 | 1.4 | 0.28 | 64 | 33 | 0.7 |

| B | 0.9 | -0.8 | 2.8 | 1.6 | 0.32 | 65 | 32 | 0.6 |

| C | 1 | -0.7 | 3.5 | 1.8 | 0.34 | 66 | 31 | 0.6 |

Wechat Us

Wechat Us