We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

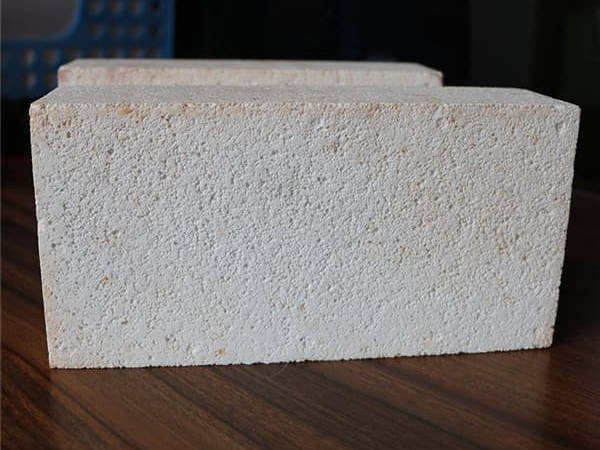

Product introduction of lightweight silica insulation brick

The manufacturing method of light silica brick is similar to that of light clay brick. Grind ordinary silica to less than 1mm, add anthracite with ash content less than 10% (particle size less than 0.2~1mm) or coal coke 30%~45%, add a small amount of lime or gypsum and pulp waste liquid, and burn it at 1270~1300 ℃ after forming and drying.

Details of lightweight silica insulation brick

The bulk density of light silica brick is 0.9~1.1g/cm3. The thermal conductivity is only half of that of ordinary silicon bricks. Thermal shock resistance is also good. The load softening temperature can reach 1600 ℃, which is much higher than that of light clay bricks. Therefore, the maximum use temperature of light silica brick can reach 1550 ℃. It does not shrink at high temperature, and even slightly expands.

Features of lightweight silica insulation brick

Lightweight silica insulation brick has excellent fire resistance, load softening temperature is close to 1620 ℃ of dense silica brick, with very small residual expansion, and its thermal stability is better than that of dense silica brick. Therefore, the light silica brick can be used for a long time under the high temperature condition (1500-1550 ℃) without contacting with the slag, and is suitable for the lining of large blast furnace supporting hot blast furnace, gas insulation layer of glass furnace, etc.

Application of lightweight silica insulation brick

Lightweight silica insulation brick is widely used in partition wall of carbonization chamber, burning chamber of coke oven, regenerative chamber of open air furnace for steelmaking, slag bag, bubble pit furnace, glass melting furnace, arch crown and bearing area of other ceramic kilns.

More relevant refractory products: Ceramic fiber rope

Parameters of silica insulation brick

| Item | QG-1.0 | QG-1.1 | QG-1.2 |

| SiO2 % | 91 | 91 | 91 |

| Refractoriness°C | 1680 | 1680 | 1670 |

| 0.2Mpa Refractoriness Under Load °C | 1480 | 1560 | 1560 |

| Cold Crushing Strength Mpa | 3.5 | 3.5 | 3.5 |

| True Density g/cm3 | 2.39 | 2.39 | 2.39 |

| Bulk Density g/cm3 | 1 | 1.1 | 1.2 |

| Permanent Linear Change On Reheating(%) | 0~+0.5 1450°CX2h | 0~+0.5 1550°CX2h | 0~+0.5 1550°CX2h |

| Thermal Conductivity (W/MK) 350°C | 0.55 | 0.6 | 0.65 |

Wechat Us

Wechat Us