We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

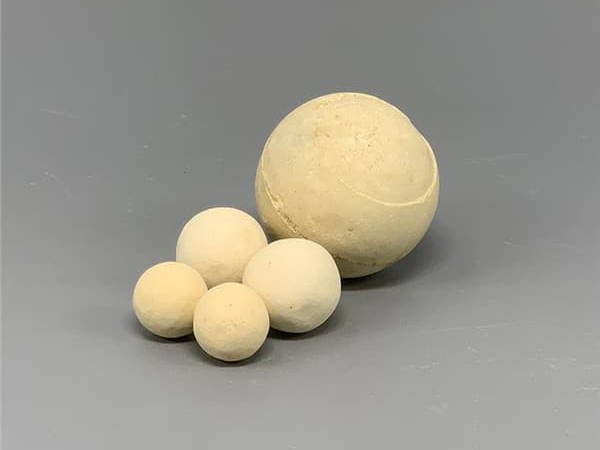

Product introduction of high alumina refractory ball

High alumina refractory ball, also known as spherical heat accumulator, has the remarkable characteristics of low shrinkage of refired line, high temperature load softening temperature, corrosion resistance, high strength, large heat storage, good thermal shock stability, good thermal conductivity, small coefficient of thermal expansion, etc. It is a refractory material with good performance.

Features of high alumina refractory ball

High alumina refractory ball has the characteristics of high mechanical strength, long service life, good chemical stability and good high temperature resistance. It has the remarkable characteristics of low shrinkage of refired line, high softening temperature of high temperature load, corrosion resistance, high strength, large heat storage, good thermal shock stability, good thermal conductivity, small coefficient of thermal expansion, etc.

Application of high alumina refractory ball

High alumina refractory balls are suitable for the combustion system of heat storage balls of gas and non-gas fuel industrial furnaces, especially for heat storage heating furnace in steel industry, heat storage ladle baker, heat storage of air separation equipment in air separation industry, heat storage melting furnace in non-ferrous metal industry, and also used as heat storage carrier in large forging plant heat storage bogie furnace, heat storage electric boiler, heat storage incinerator and other industries.

More relevant refractory products: Ceramic fibers cotton

Parameters of high alumina refractory ball

| Item | High alumina | Low creep | Mullite | Corundum |

| Size(mm) | 40-80 | 40-80 | 40-80 | 40-80 |

| Al2O3(%) | 65 | 70 | 75 | 95 |

| Refractoriness under load(°C) | 1450 | 1460 | 1530 | 1650 |

| Apparent Porosity(%) | 25 | 23 | 22 | 18 |

| Bulk Density(g/cm3) | 2.3 | 2.4 | 2.5 | 3.1 |

| Cold crushing strength(Mpa) | 13 | 14 | 32 | 36 |

| Thermal shock resistance (1100°Cwater cooling) cycle ≥ | 15 | 10 | 20 | 7 |

| Refractoriness(°C) | 1710 | 1750 | 1800 | 1800 |

Wechat Us

Wechat Us