We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

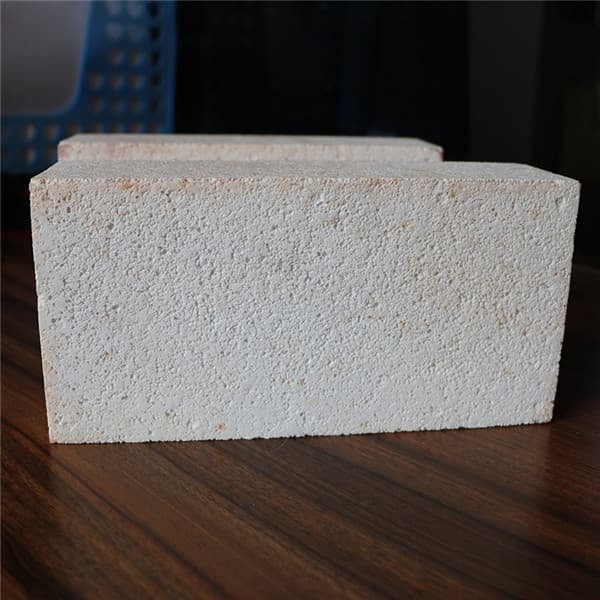

Product introduction of light weight silica brick

Light weight insulation silica bricks are generally used as raw materials such as stone and crystalline sand, with the addition of flammable substances such as coke, anthracite, sawdust, carbonized coating coating or formation of porous structures by gas precipitation. Fire resistance and hardening temperature do not differ much from those of silicone bricks. However, due to the numerous air holes, the resistance to pressure, slag, corrosion, etc., is lower than that of silicon bricks, while the resistance to thermal shock is better.

Features of light weight silica brick

High rate of air opening

Volume density

Good thermal insulation

Applications of light weight silica brick

Light weight silica brick is a very special material, which is mainly used in glass industry and steel industry. In most cases, light silica bricks and dense silica bricks are used as part of the structural layer. It is commonly used in the glass kiln industry, mainly for the thermal insulation of the kiln vault, so as to reduce the heat loss and increase the efficiency of the melting process.

Parameters of light weight silica brick

| Item | QG-1.0 | QG-1.1 | QG-1.2 |

| SiO2 % | 91 | 91 | 91 |

| Refractoriness°C | 1680 | 1680 | 1670 |

| 0.2Mpa Refractoriness Under Load °C | 1480 | 1560 | 1560 |

| Cold Crushing Strength Mpa | 3.5 | 3.5 | 3.5 |

| True Density g/cm3 | 2.39 | 2.39 | 2.39 |

| Bulk Density g/cm3 | 1 | 1.1 | 1.2 |

| Permanent Linear Change On Reheating(%) | 0~+0.5 1450°CX2h | 0~+0.5 1550°CX2h | 0~+0.5 1550°CX2h |

| Thermal Conductivity (W/MK) 350°C | 0.55 | 0.6 | 0.65 |

Wechat Us

Wechat Us