We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

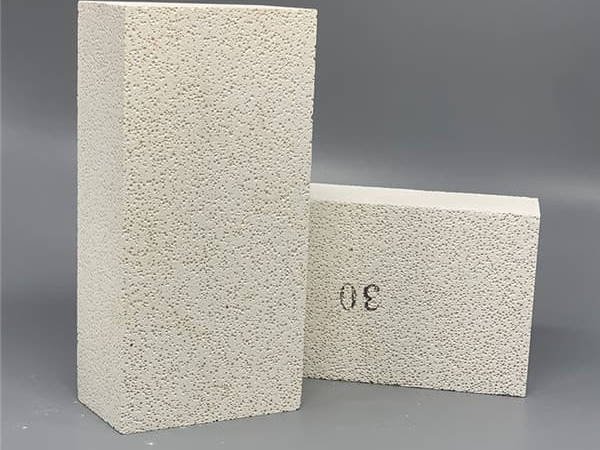

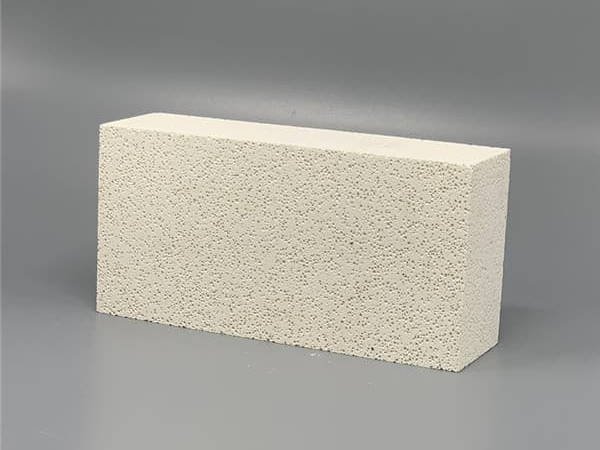

1.Product introduction of JM30 mullite insulating bricks

JM30 mullite insulating bricks shall be used as the first layer of refractory lining, or as the thermal insulation layer behind all other refractory layers, for furnaces, ovens, flues, refining and heating furnaces, regenerators, gas production plants and conduits, scheduled furnaces, stress relief furnaces, reactor chambers and similar high-temperature industrial plants.

2.Features of JM30 mullite insulating bricks

- Low thermal conductivity: It has good thermal insulation effect and can make the furnace wall thinner.

- Low heat capacity: due to its light weight and low thermal conductivity, light mullite brick series products store little heat energy, which has obvious energy-saving effect in intermittent operation kilns.

- Low impurity content: it has very low iron and alkali metal low melt content, so the refractoriness is high. The high aluminum content makes it maintain good performance in reducing atmosphere.

- High thermal compressive strength.

- Accurate overall dimensions: accelerate the masonry speed, and the brick joints are thin and uniform.

- Ensure high strength and stability of masonry.

- It can be processed into special shape to reduce the number of blocks and masonry joints.

3.Parameters of JM30 mullite insulating bricks

| Index | Volume Density | Reheating Linear Change | Cold Compression Strength | Bending Strength At Normal Temperature | Thermal Conductivity | Al2O3 | SiO2 | Fe2O3 | |

| - | - | g/cm3 | 1400℃*12h,% | Mpa | Mpa | 350℃w/m·k | % | % | % |

| JM30 | A | 1 | -0.8 | 3 | 1.8 | 0.4 | 72 | 26 | 0.5 |

| JM30 | B | 1.1 | -0.7 | 3.5 | 1.9 | 0.43 | 72 | 26 | 0.5 |

| JM32 | A | 1.1 | -0.8 | 3.6 | 1.9 | 0.43 | 75 | 23 | 0.4 |

| JM32 | B | 1.2 | -0.7 | 3.8 | 2 | 0.46 | 75 | 23 | 0.4 |

Wechat Us

Wechat Us