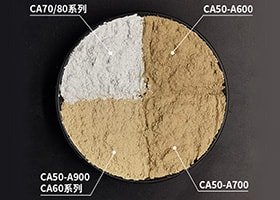

KERUI produces high purity Calcium Aluminate Cements with 70, 75 and 80% Al2O3 content by sintering process.

These products not only widely used throughout the refractory industry, but also in other areas such as building chemistry materials are in high demand.

【Description】

As a high purity product, CA80 contains approximately 80% of alumina, the specific properties of CA80 give high performance concretes the following properties, high refractoriness, excellent mechanical performance.

So it can be used in the refractory industry in conventional and low cement castables, which require fast setting, high early strength development, and good strength at intermediate temperatures. And the very high purity level of CA80 makes it suitable for certain refractory applications. For example: in reducing atmospheres where hydrogen or carbon monoxide is present, low silica and iron oxide are vital.

The 80% alumina cements of KERUI are represented by two product types, CA80 and CA80S.

”CA80S has good fluidity, long workable time and low water demand, ideal to produce castables of good working ability and excellent mechanical strength property without any additives, also it suits very well to be used in high temperature environment or hot summer time.“

Notes: refractory cement = high alumina cement = Calcium aluminate cement

| Products | CA75 | CA75 | CA80 | CA80 | CA80S | CA80S |

| Workable time | Moderate | Moderate | Short | Short | Longer | Longer |

| Standard | Usual range | Specification limit | Usual range | Specification limit | Usual range | Specification limit |

| SiO2, % | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 |

| Al2O3, % | 73.5-75.5 | ≥73 | 78.0-80.0 | ≥77 | 78.0-80.0 | ≥77 |

| Fe2O3, % | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 | 0.1-0.4 | ≤0.5 |

| CaO, % | 21.0-23.0 | - | 18.5-20.5 | - | 18.5-20.5 | - |

| R2O, % | - | ≤0.4 | - | ≤0.4 | - | ≤0.4 |

| S-, % | - | ≤0.1 | - | ≤0.1 | - | ≤0.1 |

| CI-, % | - | ≤0.06 | - | ≤0.06 | - | ≤0.06 |

| d50(μm) | 6-9 | ≤10 | 5-8 | ≤9 | 5-8 | ≤9 |

| 325M(%) | - | ≤5.0 | - | ≤5.0 | - | ≤5.0 |

| Specific surface areas(㎡/kg) | 420-480 | ≥400 | 450-500 | ≥450 | 450-500 | ≥450 |

| Setting time, min | ||||||

| Initial setting time IS | 150-200 | ≥150 | 150-210 | ≥30 | 210-270 | ≥180 |

| Final setting time FS | 240-300 | ≤360 | 210-270 | ≤300 | 260-320 | ≤360 |

| Flexural strength, Mpa | ||||||

| 1d | 6.5-8.5 | ≥4.0 | 6.0-8.0 | ≥4.0 | 5.5-7.5 | ≥4.0 |

| 3d | 8.5-10.5 | ≥5.0 | 7.0-9.0 | ≥5.0 | 7.0-9.0 | ≥5.0 |

| Compressive strength, Mpa | ||||||

| 1d | 42-52 | ≥25 | 40-50 | ≥25 | 35-45 | ≥25 |

| 3d | 52-62 | ≥30 | 50-60 | ≥30 | 50-60 | ≥30 |

【Additional Information】

Principal phase: CA, CA2, Aα

Secondary phase: C12A7

Pyrometric cone equivalent: 1750-1800℃

Bulk density: 800-900 kg/m3

Specific gravity: 3.1-3.2 g/cm3

Shelf Life: 6 months

【Packaging and Storage】

Packing method: Standard export packaging

Paper bags: 25/50kg

Big bags: 1.0/1.5mt

Storage tips:High purity calcium aluminate cements must be stored in dry conditions, off the ground. In this case, it will retain its proper ties for at least 6 months. In many instances, experience has demonstrated that properties are retained for more than one year.

Wechat Us

Wechat Us