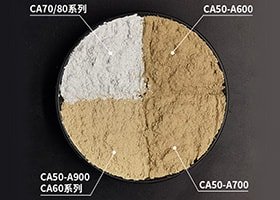

High purity Calcium Aluminate Cements with 70,75 and 80% Al2O3 content by sintering process.

High purity Calcium Aluminate Cements not only widely used in the refractory industry, but also in other areas are in high demand.

Calcium aluminate cement CA70

Calcium aluminate cement is mainly composed of calcium aluminate or calcium aluminate. High purity calcium aluminate cement CA70 contains only calcium aluminate, and the high calcium aluminate content provides characteristics that are ideal for refractory applications.

The 70%alumina cements of KERUI are represented by three product types:CA70,CA70W and CA70S.

Calcium aluminate cement CA70 has moderate setting time and hardening properties, so it shows excellent additive compatibility and dose-rate tolerance in all types of deflocculation systems.

Calcium aluminate cement CA70W has short setting time and high early strength, which is suitable for low temperature environment, especially in winter and other emergency occasions, such as quick installation or emergency maintenance.

Calcium aluminate cement CA70S is a specially formulated calcium aluminate cement that has good fluidity and lasts a long time. The castable produced by this product has good working performance and excellent mechanical strength, which is very suitable for use in high temperature environment or hot summer.

More refractory products: Kiln Lining Use Alumina Brick SK40

Notes: refractory cement = high alumina cement = Calcium aluminate cement

Calcium aluminate cement index

| Series | CA70 | CA70 | CA70W | CA70W | CA70S | CA70S |

| Workable time | Moderate | Moderate | Short | Short | Longer | Longer |

| Standard | Usual range | Specification limit | Usual range | Specification limit | Usual range | Specification limit |

| SiO2, % | 0.2-0.7 | ≤1.0 | 0.2-0.7 | ≤1.0 | 0.2-0.7 | ≤1.0 |

| Al2O3, % | 68.5-70.5 | ≥68 | 68.5-70.50. | ≥68 | 68.5-70.5 | ≥68 |

| Fe2O3, % | 0.1-0.5 | ≤0.7 | 1-0.5 | ≤0.7 | 0.1-0.5 | ≤0.7 |

| CaO, % | 28.5- 29.5 | - | 28.5-29.5 | - | 28.5-29.5 | - |

| R2O, % | - | ≤0.4 | - | ≤0.4 | - | ≤0.4 |

| S-, % | - | ≤0.1 | - | ≤0.1 | - | ≤0.1 |

| CI-, % | - | ≤0.06 | - | ≤0.06 | - | ≤0.06 |

| d50(μm) | 44149 | ≤14 | 44022 | ≤10 | 44149 | ≤14 |

| 325M(%) | - | ≤8.0 | - | ≤5.0 | - | ≤8.0 |

| Specific surface areas, ㎡/kg | 380-420 | ≥350 | 400-450 | ≥400 | 380-420 | ≥350 |

| Setting time, min | ||||||

| Initial setting time IS | 180-240 | ≥150 | 60-120 | ≥30 | 240-270 | ≥180 |

| Final setting time FS | 240-300 | ≤360 | 120-180 | ≤240 | 300-360 | ≤360 |

| Flexural strength, Mpa | ||||||

| 1d | 9.0-11.0 | ≥5.0 | 9.0-11.0 | ≥5.0 | 8.0-11.0 | ≥5.0 |

| 3d | 11.0-12.0 | ≥6.0 | 11.0-12.0 | ≥6.0 | 11.0-12.0 | ≥6.0 |

| Compressive strength, Mpa | ||||||

| 1d | 45-55 | ≥30 | 45-55 | ≥30 | 45-55 | ≥30 |

| 3d | 55-65 | ≥40 | 55-65 | ≥40 | 60-70 | ≥40 |

【Additional Information】

Principal phase: CA, CA2

Secondary phase: C12A7, Aα

Pyrometric cone equivalent: 1580-1620℃

Bulk density: 850-950 kg/m3

Specific gravity: 2.9-3.1 g/cm3

Shelf Life: 6 months

Wechat Us

Wechat Us