We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

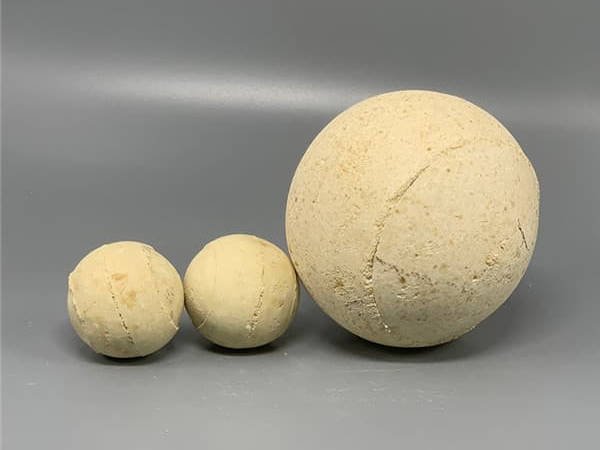

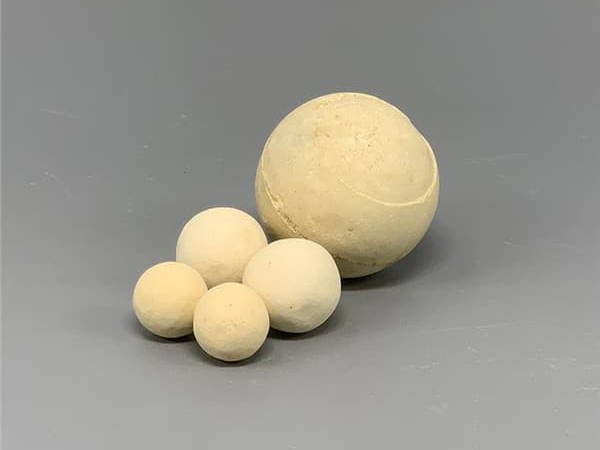

High density alumina ball introduction

High density alumina ball has high mechanical strength, long service cycle, good chemical stability, good high temperature resistance and other characteristics, high temperature gas and air through the high aluminum refractory ball, in the same path it can preheat to only about 100℃ lower than the flue gas temperature, temperature efficiency up to 90%.

High density alumina ball features

- High mechanical strength, long service cycle

- Good chemical stability, no chemical reaction with materials

- Good high temperature resistance, the highest heat resistant temperature of refractory porcelain ball can reach 1900 degrees

High density alumina ball application

Through double preheating of gas (blast furnace, converter) and air (oil, high calorific value gas, etc., adopts single heat storage mode of combustion air), the high density alumina ball can reduce the smoke emission of regenerative heating furnace by 20-50%, reduce the smoke emission temperature to less than 150 degrees, increase the output by 15-20%, shorten the billet heating time by 50%, and reduce the oxidation burn loss by 30-50%.

More relevant refractory products: Ceramic fiber board

High density alumina ball standard size:

| Item | High alumina | Low creep | Mullite | Corundum |

| Size(mm) | 40-80 | 40-80 | 40-80 | 40-80 |

| Al2O3(%) | 65 | 70 | 75 | 95 |

| Refractoriness under load(°C) | 1450 | 1460 | 1530 | 1650 |

| Apparent Porosity(%) | 25 | 23 | 22 | 18 |

| Bulk Density(g/cm3) | 2.3 | 2.4 | 2.5 | 3.1 |

| Cold crushing strength(Mpa) | 13 | 14 | 32 | 36 |

| Thermal shock resistance (1100°Cwater cooling) cycle ≥ | 15 | 10 | 20 | 7 |

| Refractoriness(°C) | 1710 | 1750 | 1800 | 1800 |

Wechat Us

Wechat Us