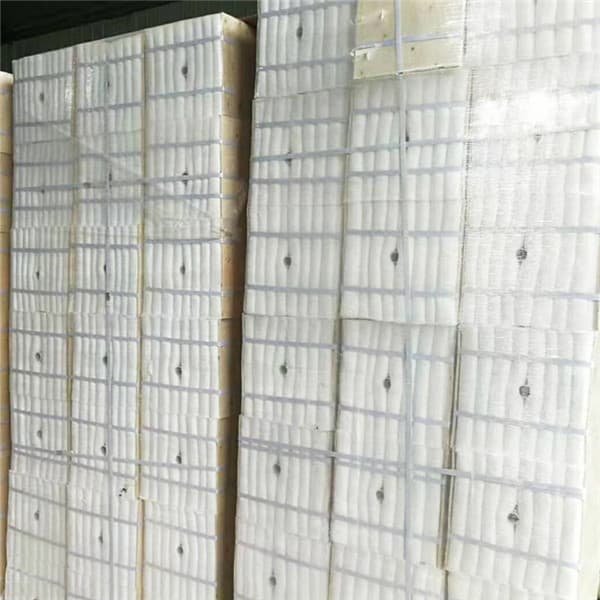

Ceramic fiber module is a new type of refractory lining product to simplify and accelerate the construction of kiln and improve the integrity of furnace lining. The product is white in color and regular in size, can be fixed directly on the anchoring nail of steel plate in the furnace shell of industrial kiln. Classification temperature: 1050-1400℃.

Performance Characters

- Excellent chemical stability.

- Good thermal stability.

- Excellent elasticity, ceramic fiber module in the preloading state, after the completion of lining masonry, the expansion of ceramic fiber module makes the lining seamless and can compensate the shrinkage of fiber lining to improve the insulation performance of fiber lining and good overall performance.

- Ceramic fiber module can be installed quickly, and the anchor is set on the cold surface of the wall lining, which can reduce the material requirement of the anchor.

Application

- Ceramic industry: tunnel kiln, shuttle kiln, roller kiln.

- Petrochemical industry: atmospheric pressure furnace, converter, coking furnace, cracking furnace, heating furnace, flue, etc.

- Steel industry: ladle cover, heating furnace, annealing furnace, hood furnace, stepping furnace, hot air pipes and pipes, etc.

- Environmental protection and energy saving industry: waste incinerator, RTO waste gas treatment furnace, SCR environmental protection catalytic furnace, etc.

| Type | - | HR1050 | HR1260ST | HR1260HP | HR1350HA | HR1430Zr | HR1600PMF |

| Classification Temperature, ℃ | - | 1050 | 1260 | 1260 | 1350 | 1430 | 1600 |

| Linear Shirinkage,% 192kg/m3/at(24h)℃ | - | ≤2.0 (850℃) | ≤2.0 (1000℃) | ≤2.0 (1050℃) | ≤2.0 (1100℃) | ≤2.5 (1200℃) | ≤1.5 (1450℃) |

| Bulk & Density, kg/m3 | - | 172-240 | 172-240 | 172-240 | 172-240 | 172-240 | 172-240 |

| Thermal Conductivity, W/m.k | 400℃ | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | - |

| 600℃ | 0.15 | 0.15 | 0.15 | 0.12 | 0.12 | 0.12 | |

| 800℃ | 0.22 | 0.2 | 0.19 | 0.18 | 0.16 | 0.15 | |

| 1000℃ | - | - | 0.22 | 0.12 | 0.19 | 0.18 | |

| Chemical Analysis, % | Al2O3 | 42-44 | 45-46 | 47-49 | 52-55 | 34-36 | 72-75 |

| Al2O3+SiO2 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | |

| ZrO3 | - | - | - | - | 15-17 | - | |

| Others | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

Wechat Us

Wechat Us