We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

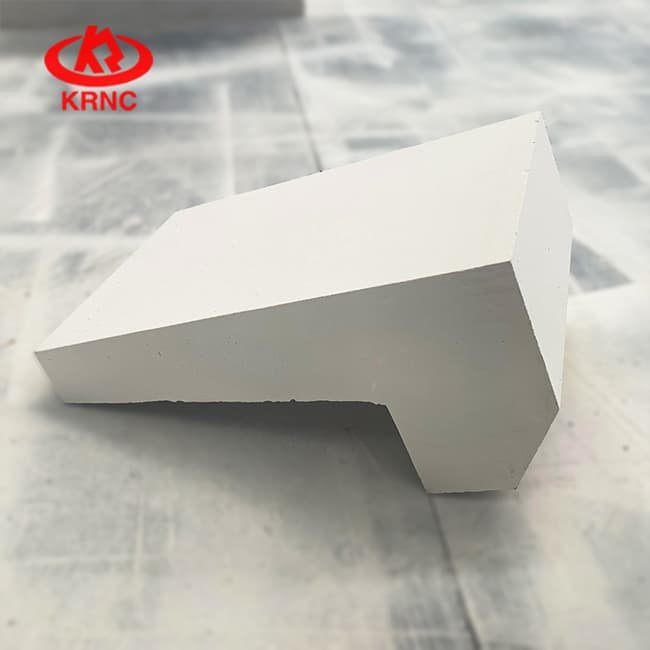

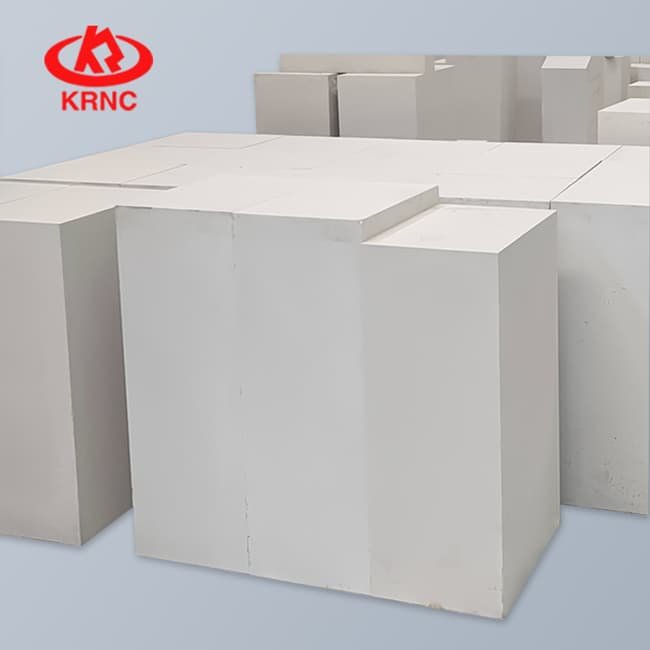

Description of AZS-36 firebrick

In addition to having the same eutectic as AZS33 fused zirconia corundum brick, the corrosion resistance of AZS36 fused zirconia corundum brick is further enhanced due to the increase of more interlocking zirconia crystals and the decrease of glass phase content.

Chemical index of AZS-36 firebrick

| Chemical composition(%) | |

| ZrO2 | ≥35 |

| SiO2 | ≤14 |

| Al2O3 | rest |

| Na2O | ≤1.45 |

| Fe2O3+TiO2 | ≤0.30 |

Physical properties of AZS-36 firebrick

| Physical properties | |

| Cold crushing strength(MPa) | ≥350 |

| Exudation temperature of glass phase(ºC) | ≥1400 |

| Erosion-resistant to molten glass(mm/24hr) | ≤1.5 |

| Bulk density(g/cm3) | |

| NC | ≥3.45 |

| VF | ≥3.75 |

Phase composition of AZS-36 firebrick

| Phase composition(%) | |

| Baddeleyite | 35 |

| Glass phase | 18 |

| alpha-corundum | 47 |

Application of AZS-36 firebrick

The corrosion resistance of AZS36 fused zirconia corundum brick has been further enhanced, and the pollution to the liquid glass has been further reduced. Therefore, it is suitable for areas where the flow rate of the liquid glass is fast and the temperature is high, such as the wall brick of the melting pool, the paving brick, the charging hole brick, etc.

Wechat Us

Wechat Us