Refractory ceramic fiber products are a kind of insulating material made of alumina silica fiber. These fibers are highly resistant to high temperatures and thermal shock, making them ideal for high temperature applications. Ceramic fibers can be woven or spun into a variety of products, including blankets, boards, paper and tubes.

Ceramic fiber blanket is easy to install and can be used in a variety of applications. They are commonly used in industrial furnaces to insulate the walls and floors of furnaces. They can also be used in the production line of kilns and other high-temperature equipment. Ceramic fiber felt is also used in the automotive industry to isolate exhaust systems and other high-temperature components.

Refractory ceramic fibreboard is rigid and has excellent insulation property. They are used in applications that require molding or processing materials, such as furnace and kiln linings, and the manufacture of high-temperature insulating washers.

Ceramic fiber paper is a flexible, lightweight insulating material used in a range of high temperature applications such as exhaust systems and industrial oven insulation. The paper can be easily cut and shaped to meet the requirements of the application.

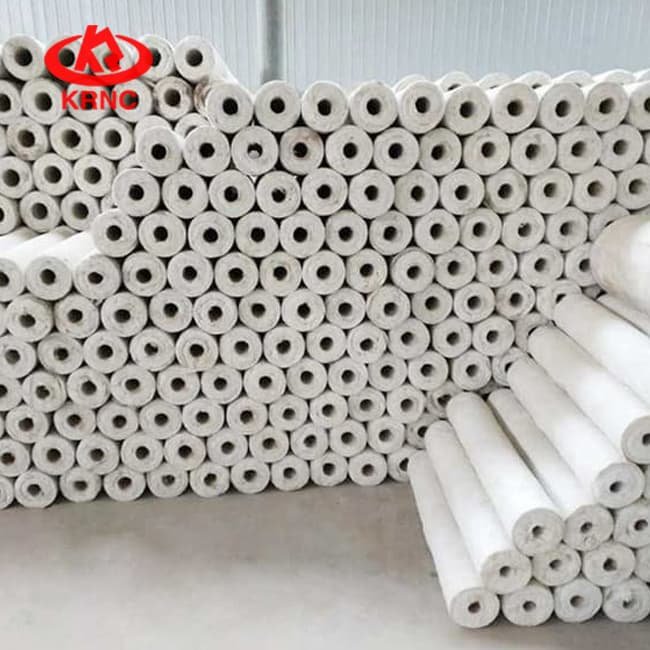

Ceramic fiber tubes can withstand temperatures up to 2600°F, making them ideal for high-temperature applications. They also have low thermal conductivity, which means they insulate and prevent heat loss.

Advantages of ceramic fiber products

Ceramic fiber products can withstand temperatures up to 2400°F, making them ideal for high temperature applications.

Ceramic fiber products are very durable and can withstand harsh environments. They are resistant to chemicals, water and fire.

Ceramic fiber products are light weight and easy to handle. They are well suited for applications where weight is a problem, such as in the aerospace industry.

Ceramic fiber products can help save energy by reducing heat loss in high temperature applications.

Wechat Us

Wechat Us